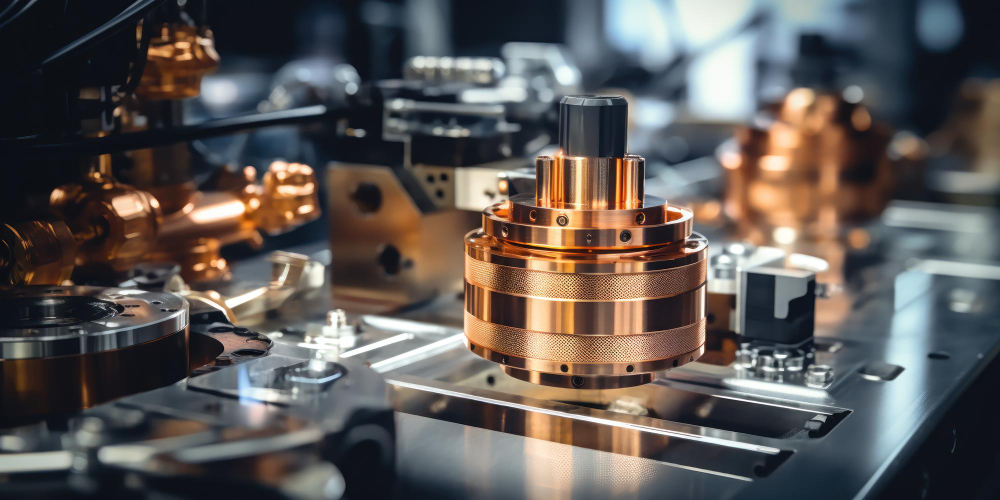

You know that using the right tools can make a world of difference. Carbide cutting tools, with their tungsten carbide drill bits, bring an edge to the table, literally. They slice through material with ease and precision you’ll appreciate.

These tough-as-nails bits lead to less wear over time, leaving more money in your pocket for other shop needs. As they maintain sharpness longer than standard ones do, they keep operations humming smoothly at peak performance levels while delivering stunning finishes on every piece crafted. Speaking of longevity, maximizing tool life is something carbide excels at!

Maximizing Tool Longevity with Carbide

To maximize your carbide threading tools’ life, choose the right grade for your project. Tougher grades suit hard materials; wear-resistant ones excel in high-speed threading. Regular maintenance is key, clean and inspect to prevent premature failure.

Use coolant systems during machining with tungsten carbide drill bits to dissipate heat and improve chip flow, maintaining the quality of work. Correct tool setup ensures precision cuts by router bits while programming techniques optimize efficiency, reducing cycle times significantly. With cutting applications, select proper tool geometries tailored to material characteristics for optimal performance and surface finishes

Achieve Superior Finishes Using Tungsten Bits

Tungsten bits are integral for achieving superior finishes in precision machining. Incorporating tungsten carbide end mills from Suncoast Precision Tools enables the creation of intricate parts with strict tolerances.

- Precision Cutting: Suncoast’s 8mm End Mill offers remarkable precision, crucial in sectors requiring stringent tolerances. Its advanced geometric design allows working with diverse metals effectively. Tungsten’s hard composition translates into cleaner cuts and finer detail on final products. Such accuracy is particularly vital for aerospace and medical components, where deviations can be costly.

- Thermal Management: Solid carbide tools embody excellent thermal conductivity, essential during extended periods of cutting operations. The heat dissipation properties inherent to these materials help maintain a stable temperature at the point of contact. This quality prevents tool degradation due to excessive heat exposure. Thus, you achieve more consistent surface finishes while extending your tool’s life span.

- Advanced Flute Design: Innovation flourishes within the specialized flute configuration of Suncoast’s end mills. Chip evacuation efficiency climbs markedly thanks to this feature, it keeps chips from recutting. Extending its utility across industries confirms its versatility as a choice among professionals. And not least, each mill undergoes rigorous testing, ensuring performance adherence so users receive reliable instruments every time.

Bottom line: when cost-effectiveness counts in your operations over time, especially if paired with modern CNC machinery where precision meets productivity, opting for Suncoast Precision Tools’ range would serve you well across various materials and applications.

Carbide cutting tools offer exceptional durability, maintaining their sharp edge longer than traditional materials. This means fewer tool changes and consistent precision in your cuts. Their resistance to heat aids performance on tough materials, ensuring a quality finish while boosting productivity.

By opting for carbide end mills from Suncoast Precision Tools, you enjoy increased efficiency in machining tasks with the bonus of reduced downtime; this translates into cost savings over time. For any serious machinist aiming to elevate work quality and turnaround time, these tools are an essential investment.